|

IButton Reader The TempTec-R Reader is a hand held data gatherer that can download files from the iButton data loggers just by touching them. The TempTec Reader can hold files from a large number of iButton data loggers before off-loading the files to the PC. The TempTec-R shows immediately if any temperature problem has occurred without having to download the file to a computer.

Temperature monitoring system for transport and storage of perishable goods Features The system uses the small iButton data loggers. The iButtons are started by the PC, if desired with alarm limits using the communications program in the software and USB interface to the computer.

The iButtons are then positioned in the storage area in wall mounted fobs or mounted in coloured keytag fobs packed with goods. When the files are wanted, the user can walk up to the iButtons and gather their files by touching them with the TempTec-R reader.

An iButton is a chip housed in a stainless steel enclosure. The electrical interface is reduced to the absolute minimum, i.e., a single data line plus a ground reference. The energy needed for operation is 'stolen' from the data line ('parasitic power'). The logical function of the DS1990A is a simple serial number. This globally unique registration number is common to all iButtons.

For read operations all devices are satisfied with a 5kOhm pull-up resistor to supply energy and to terminate the 1-Wire bus. The I Button Reader application was designed to be a small interface that can read data from iButton device. System requirements. iButton device.

Ibutton Read Diagram

An iButton is a computer chip which is enclosed in a 16mm thick durable weather resistant stainless steel can. Because of their small size and extreme durability, iButtons can travel virtually anywhere. IButtons are frequently attached to key fobs, rings, watches, or other personal items for applications such as access control to buildings and computers. Additionally, iButtons are commonly mounted to storage crates, trucks, and other equipment for asset management. Furthermore, iButtons are mounted to refrigeration units, outdoor environments, and even to animals for various data logging tasks.

IButton varieties include. Address Only - Guaranteed unique 64-bit serial numbers (i.e. Address & ROM id) ideal for access control and route verification applications. Models include the &. Memory - Data can be stored in NVRAM, EPROM (write once read many) and/or EEPROM. Models range from 1K bits to 64K bits. Real Time Clock - Supplies a unique way to maintain time in applications e.g.

Calendar, stopwatch, hour meter & Time/Date Stamps. Secure - Data can be protected with SHA-1 (Secure Hash Algorithm) or password protection depending on the level of security required. Temperature & Data Loggers - The provide a ideal logger for applications requiring an inexpensive and robust light weight logger.

The Memory iButtons are available with a number of types of Memory: EEPROM - This memory can be written and rewritten many times. However, they do have a lower write cycle limit (and price tag typically) than NV RAM. 256 Bit EEPROM iButton.

4Kb Bit EEPROM iButton. 32KB Password Protected EEPROM Memory iButton. EPROM - This memory can be written once and read many times. It is ideal for applications were the data needs to be written permanently. To program EPROM memory, a higher programming voltage (12V) is required than most 1- Wire adapters provide. We suggest using the DS9097U-E25# programming/writing to the EPROM Memory. 1Kb 'Add Only' EPROM Memory iButton.

NV RAM - This memory can be rewritten to millions of times. They are ideal for applications requiring the memory to be constantly accessed and modified. The Monetary iButton® provides 4Kb of SHA encypted NV RAM.

1Kb NV RAM Memory iButton. 4Kb NV RAM Memory iButton. 4Kb NV RAM Memory iButton with Clock. 64Kb NV RAM Memory iButton.

Rugged temperature logger with ±1.0°C accuracy. The recording is done at a user-defined rate, as both a direct storage of temperature values and in the form of a histogram. Up to 2048 temperature values are taken and stored at equidistant intervals ranging from 1 to 255 minutes. temperature logger with ±1.0°C accuracy and an operating range is 15°C to 46°C. This unit offers higher resolution (0.125°C) than the DS1921G model over a restricted temperature range. It makes the economical choice for applications which remain withing the operating range. temperature logger with ±1.0°C accuracy and an operating range of -5°C to 26°C.

It offers a higher resolution (0.125°) than the DS1921G. This makes the DS1921Z preferrable in applications that will remain within th -5°C to 26°C operating range. high temperature logger is designed to provide data logging in applications up to 140°C. When housed in the DS9107+ iButton capsule, it is capable of confirming autoclave performance. this temperature logger covers the same wide general purpose temperature range of -40°C to 85°C as the DS1921G does, but it provides superior accuracy (±0.5°C), resolution (Up to 0.0625°C), and capacity (up to 8192 readings). high temperature logger which monitors temperature from above boiling down to freezing (0°C to 125°C). this temperature and humidity logger has all the features of the DS1922L with humidity logging and a -20°C to 85°C operating range.

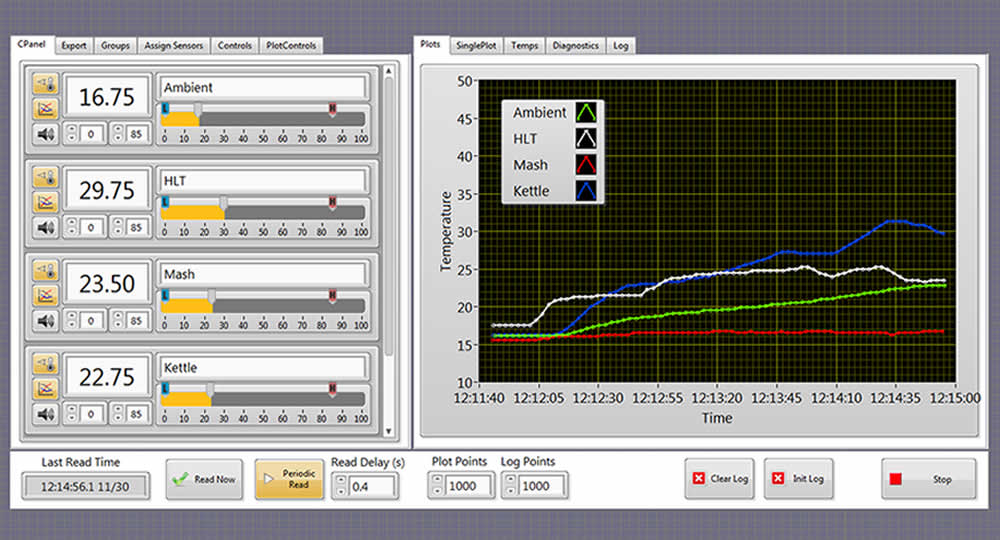

Reading Software

Real-Time Clock iButton. Real-Time Clock iButton with 4Kb NV RAM.

IButton Accessories iButton Accessories are a suite of products which enable the iButtons to read, written to, and deployeed in wide variety of applications. The accessories fall into a number of general categories:. Cables - These typically provide a connection between the iButton and the Reader. Mounting Options - Provides an range of options for mounting iButtons which includes snap-in fobs, screw mounting brackets, adhesive pads, & more. Readers - The provide the iButtons data over a variety of interfaces: USB, Ethernet, and RS232.

Software - These all have the capability to configure and download Temperature Data Logging iButtons. The 1-Wire Viewer package also has the capability to work with al iButton models.

Update Drivers Choose to automatically download the correct Windows ® Drivers. Windows ® 10, 8, 7, Vista & XP. Software company. Microsoft and Windows are. This download installs the Intel® PRO/Wireless driver version 9.0.4.39 for Windows XP*. PRO/Wireless Drivers-Only for Windows XP*. Driver or software updates. Network Adapter Drivers for Windows XP*. Run Intel® Driver & Support Assistant to automatically detect driver or software updates. Intel® PRO/100. For automatically update and install any Windows XP device drivers. Intelligent software customizes driver updates. Windows 8.1/8, Windows 7, Vista, XP Pro. Update windows xp drivers. Windows ® XP Driver. Between a hardware device and software. Drivers create. Install the updates. Common Windows ® XP Driver.

Components - Miscellaneous items used with the iButtons. Part Number Mounting Surface iButton Removable Compatible With Multiple Colors Available Waterproof DS1404+ Wall - DS1402 Cables No No DS9093A Key Ring No F5 iButtons Yes No DS9093F+ Key Ring Yes Any iButton No No DS9093N+ Key Ring Yes F5 iButtons No No DS9093RA+ Plastic Card Yes F5 iButtons No No DS9093RB+ Plastic Card Yes F5 iButtons with DS9093RA+ No No DS9093S+ Wall Yes F5 iButtons No No DS9094F+ PCB Through Hole Yes F5 iButtons No No DS9096P+ Flat Smooth Surface No Any iButton No No DS9098P+ PCB Surface Mount Yes F5 iButtons No No DS9107+ Clamps to Cable Yes F5 iButtons No Yes. Software Package Recommended # of Loggers Writes User Friendly Labels Data Reporting Capability Mission Start Delay Functionality Export Data Options Data Storage 1-Wire Viewer 25 or Less No View reports on screen Must calculate delay in minutes Yes, via.csv format No Thermodata Viewer Unlimited Yes Print custom reports & graphs Delay selected by desired date & time Yes, via.csv format Can save and reload CSV files Thermochron Server Unlimited Yes Print reports & graphs Delay selected by desired date & time Yes, via.xml or.csv format Stores up to 1000 downloads locally.

I've made an iButton garagedoor opener and logger. On a Dutch (kind of) eBay I found some iButtons and readers very cheap. I had no idea what to do with them, but I bought them anyway. My garage opens with a push on a button, so it must be possible to get that working with the iButton. I also found some really cheap (0,50 euro) displays, so it would be nice if I also can make a screen to show me who entered when. The project is now existing in three parts:.

The iButton opening the door. A clock keeping track of times and dates.

A screen showing the information So to keep things understandable I try first to figure out the three parts separately. Start playing with it So I bought the parts. Now I had to find out how the things work. Trough the Arduino-site (www.arduino.cc) I found the 'Fridzing' drawing on I also found the 1-Wire library there. 1-Wire is the name of the communication method used by the iButtons. With this drawing and the library it was easy to wire everything and get it running. How to wire up According to the schematics, I took my Arduino, a breadboard, the iButton reader, a 2,2 kOhms resistor, three wires and a LED. I wired it a little bit different than the drawing.

My iButton reader had only two wires. Before I went any further I first wanted to check wether the button opening my garage really worked by just connecting two wires. To be sure that I didn't kill myself, I first measured how much volts are going trough the button. I simply removed the button from the wall and put my multimeter on the two screws on the back. I had a reading of 21 V DC, so that might bite, but probably won't kill me if I accidentally touch it.

Now I simply connected the two screws with a piece of wire and the door opened. Adding the relay My theory worked so now it was time to add the relay to my design. On the 'Fritzing' drawing you can see how I did that. I moved the iButton to port 12 to make more room on the Arduino to ad the clock and the LCD later on. The Arduino will switch the transistor (I used a BC338 that I had laying around, but any 5V NPN general purpose will probably do) and the transistor will switch the relay. The green wires going from the relay will be connected to the screws on the back of the button that opens the garage. The diode should be there to help the relay.

(I'm not sure why anymore, but just put it there, the relay will live longer). Finally the LCD arrived. Now I need to figure out how the thing works, so again, www.arduino.cc is my friend. I found the LCD-library and sketches.

The next step is connecting the LCD to the Arduino according to the drawing on the Arduino-site. I had some old flat cable laying around that I used to connect the LCD. I don't have the right connectors, so I used some other connectors that I did have. Shielding them with 'shrinktubes?'

Makes them very usable. Two pins on the LCD should be connected to the GND so I make a little wire bridge. The pin-setting on my LCD is not in one row but like this: 15 - 16 13 - 14 11 - 12 9 - 10 7 - 8 5 - 6 3 - 4 1 - 2 Only pin 1 and pin 15 are marked. One wire should go through a 10 kOhm potmeter. This was a problem when I wired everything up. I wired everything exactly like on the Arduino site and ran the sketch that comes with the Arduino software, but it seemed like the LCD was not working.

After trying everything and checking all wires ten times, I turned the potentiometer all the way down and it worked! Al the parts work separately on the breadboard. Now it is time to put them al together on a PCB. The PCB I'm not into etching and making your own PCBs, so I will put everything on a 'hole-board'. First put in all your components and then start wiring and soldering.

I colored the +5V on the back of my PCB red and the GND black. I added some header-pins so I can pin my PCB on top of the Arduino. The corner of the PCB above pin 12 of the Arduino had to come off because it was not in line with the holes in my board. The wire going to pin 13 on the drawing is moved to pin 7.

Pin 13 will blink when the Arduino starts up, so that means that the garage door would open and close and open and close every time the Arduino starts up. In the separate sketches I made (and copied from others), I changed the pin numbers to the pins that are used now and I ran all three sketches. Everything is working! To fit everything, I'm going to make an aluminum housing. It will be 13 cm x 8 cm x 6 cm. First make a drawing.

(this is a good moment to find flaws in your design). Get a piece of aluminum. Cut out the pieces (or saw if you don't have have a cutter). Next you bend it in the right shape. (if you don't have a bender, you can do it on the edge of a table, using a steel profile and wood clamps). To hold the Arduino and PCB, you need to drill holes in the bottom.

You can mark these through the holes in the Arduino-board. With some bolts (M3 = 3mm), you can montage the Arduino. One bolt should go through the PCB. You will need this later to fine-tune the buttons on the PCB.

Drill the holes in the top plate. The top plate should support the LCD and the rods going to the buttons. Drill the holes on the places where the holes in the LCD are and right above the buttons on the PCB. You also need holes at the four corners of the front plate. With a Dremel (or wannabe Dremel) you cut out the hole for the LCD. You need to cut it a little bit to small.

With a file in a vise you make the hole the right size. If you want, you can spray paint the case. (I just painted the front black). For the buttons I used slot bolts, but they are just to close to each other so I have to make them a little bit smaller on one side. Make the holes above the buttons square if you want to use slot bolts as buttons.

Cut two bushes so they are just long enough that it fits between the top plate and the buttons on the PCB. There must be enough space in-between to fit a nut (I used a nylock nut).

Next you need to glue the bushes in place. (I use hot glue because I like hot glue). Cut the slot bolts exactly the right size and keep them in place with the nut.

Screw the top plate in place. Finetune the buttons with the little nut under the PCB. Next make the sides of the box.

(I used perforated material that fits snugly, so I don't need to use bolts). Drill holes in the side plates for the cables. Connect the cables going to the garage door opening button and to the iButton-reader. (put the cables trough the holes in the side plates).

Put everything together. Finally I made the bolts black with a marker.

Rapidly build business solutions using Microsoft Visual Studio 6.0, the complete enterprise development tool suite. Winner of the PC Magazine Technical Excellence Award, as well as the PC Computing MVP Award, Visual Studio allows you to build scalable applications for Windows and the Web that easily integrate with existing systems.??Visual Studio 6.0 Professional Edition includes the complete set of development tools for building reusable applications in Microsoft Visual Basic 6.0, Visual C++ 6.0, Visual J++ 6.0, Visual FoxPro 6.0. Microsoft visual studio torrent download. To take advantage of the latest capabilities for developing Windows 2000 and mobile computing applications, Visual Studio 6.0 now includes the Windows 2000 Developer's Readiness Kit and the freely redistributable, SQL Server 7.0-compatible Microsoft Data Engine (MSDE) for mobile applications. Included Visual InterDev 6.0 provides easy integration with the Internet and a full Web page authoring environment.

To finnish it al up, we just need to connect everything. The iButton-reader has to go though the doorframe to the outside. You need to drill a hole for the wire to go trough. 4 mm is big enough. If you drill this hole from the outside in, you want to drill slightly upwards, so water can not run in.

On the outside you need to make the hole a bid bigger. In my case; 10 mm for the body of the iButton-reader and 18 mm for the outer rim. I had to make the wires a little bit longer to get to my controller.

Be careful nog to switch the wires around. Now it is easy to install the iButton Reader. The wires coming from the relay should go to the screws on the back of the button that opens the garage. It doesn't matter what way around.

Now it is time to plug the Arduino in and see if it is working! I gave the garage door-opener a couple of functions:. On the top-line of the LCD you can see the time and date. On the bottom-line you can see who entered last including the time and date, he entered. If you push the top button, you can set the clock and first change the hour by pushing the bottom-button. If you push the top-button again, you change the minutes with the bottom-button.

Next comes date and month. If you push the bottom-button, you can skip trough the 10 last entries. Every time you push the bottom-button, you will go back one in time. When you first push the bottom-button and than the top-button, you can block or de-block iButtons. All iButtons will appear with the question to block it: top-button is yes, bottom-button is no.

Comments are closed.

|

AuthorWrite something about yourself. No need to be fancy, just an overview. ArchivesCategories |

RSS Feed

RSS Feed